Custom Flavors produces flavors that are uniquely designed to suit your food or beverage formulation, facilitating a seamless integration of the flavor into your product.

Experience a new standard

of Flavor Development and Customization

You can enjoy premium quality natural flavors along with the necessary regulatory documentation without enduring lengthy waiting periods.

The experienced team at Custom Flavors provides valuable guidance and direction during product development, which helps you to save time, money, and expedite your product’s market entry.

Our goal is to not only deliver exceptional quality but also help your product stand out by providing natural flavors that integrate seamlessly into any food or beverage formulation.

Our Capabilities For You

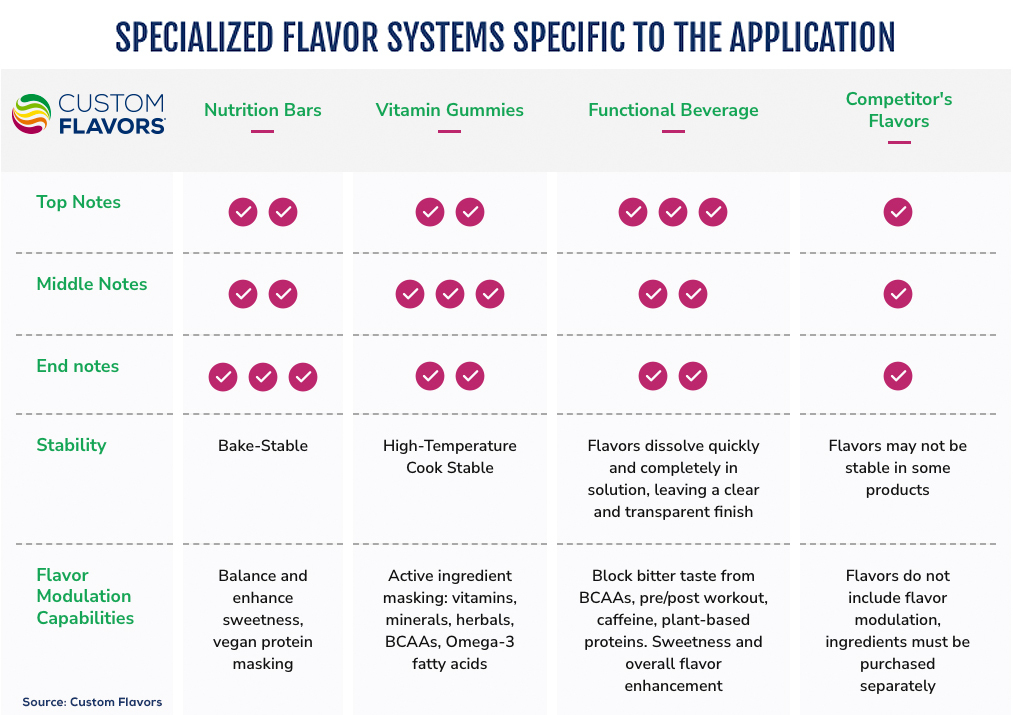

At Custom Flavors, our passion, commitment and experience come through in every flavor we develop. Let us show you how art and science create the quality that sets your product apart. We use the best ingredients and ensure that each made-to-order flavor is uniquely formulated. The flavors we create either enhance the taste of foods and beverages or mask unwanted off-notes in products.

Our flavor chemists and food scientists craft extraordinary flavors for supplements, food and beverage manufacturers. Our client list includes popular and well-known brands in nutraceutical and dietary supplements, sports drinks, baked goods, beverages, dairy products, confectionery items and more.

SPECIALLY DESIGNED FLAVORS

Every day customers come to us with flavor ideas. Our team has the skill and flexibility to create customized flavors exactly the way that you want them. To date, our portfolio includes more than 20,000 distinct flavors. At Custom Flavors, we bring passion and creativity to meet our customer’s high expectations and make extraordinary, unique flavors.

PRODUCT DEVELOPMENT

After decades in the business, we’re also happy to share our experience in product development. We work with customers who have well-established brands and products as well as startups with little more than a flavor concept and an idea. It can take persistence to get the flavor just right and bring the product to market. Our exceptional flavors, client-focused customer service and industry expertise offer our clients a value-added partner in the flavor industry and provide long-term competitive advantages.

REGULATORY SUPPORT

Our team has developed efficient systems that assist in getting your product approved, certified and to market. We maintain a database of over 50,000 regulatory documents for your convenience. By providing prompt and accurate information, we help your project move along more smoothly.

FLAVOR MATCHING

Our flavorists have analytical resources available to match any flavor with our state-of-the-art GC/MS equipment. Accurate, timely flavor matching allows you to improve your current lead times, cost, service and delivery. We can convert current products to new formats, such as Natural, Non-GMO or Organic. All of this improves your product and the bottom line.

Quality Control is Part of Our Culture

Custom Flavors adheres to strict quality assurance and quality control measures to ensure our flavors consistently meet industry and customer demands. We start by sourcing key ingredients and raw materials that meet our rigorous standards, then produce and package our finished flavors with a quality-first mentality.

We run our business on a specially designed Total Quality System based on multiple levels of qualification and verification. In addition, we undergo 3rd-party audits to meet or exceed the latest in industry-recognized standards.

Quality is embedded in our culture. Every employee understands they are part of the process. We invest in ongoing training and re-qualifying for quality compliance practices in our work.

OUR PRODUCTS FEATURE:

Quality Ingredients

- Supplier and vendor approval program

- Ingredient screening and approval process

- In-house and 3rd party testing

Quality Production

- Complete traceability of all materials and food contact packaging used in-process

- Ingredient weight and lot code verification at point of addition

- State-of-the-art facilities and equipment

Quality Post-Production

- Continuous monitoring and analysis of all operations to improve quality

- Overall emphasis on safety, efficiency and service

- Continuous review of all quality documentation and testing results to ensure compliance with specifications

Quality Control Testing Methods

- Our trained QC staff conducts product-specific testing to ensure quality for every flavor we produce. This includes, but is not limited to: organoleptic testing (taste, visual, and odor testing) and specific gravity. For certain applications, flash-point analysis and Gas Chromatograph Mass Spectrometry (GC-MS) are utilized.

Complete Regulatory Services

- Our regulatory team provides our customers with a wide range of regulatory assistance and can support efforts towards meeting Non-GMO, All-Natural, Organic, Kosher, and many other initiatives

Quality Documentation

- Certificates of Analysis (COAs)

- Safety Data Sheets (SDS)

- Specification Sheets

- Kosher Certifications